Gamma and Neutron detection technology, developed by Photonis Nuclear Instrumentation, is a cutting-edge field that significantly contributes to nuclear safety and research.

With their expertise in designing and manufacturing neutron and gamma detectors, Photonis, part of Exosens plays a vital role in ensuring the safety and control of nuclear reactors, fuel reprocessing plants, waste storage facilities, and research centers.

Photonis manufactures and sells technologies in the field of photo-detection and low light conditions imaging.

Neutron detection as a technology

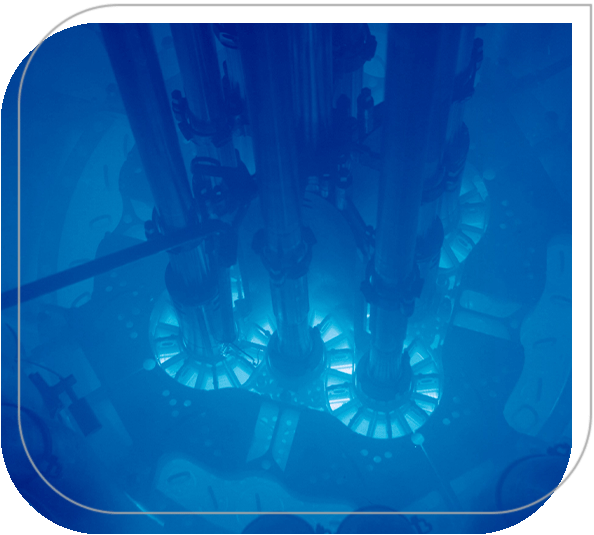

As a neutron has no charge, a neutron detector must incorporate a neutron-to-ionized particle converter. The incident neutrons are captured by the converter material which then produces (detectable) ionized particles by means of a nuclear reaction.

Photonis gas-filled detectors are designed to detect thermal neutrons (neutron energy < 0.025 eV), so the probability of neutron capture (capture cross-section) of the detecting material must be as large as possible for this low energy. We therefore use 235U (580 barns at 20 °C) for our fission chambers, and 10B (3840 barns at 20 °C) for our boron-lined proportional counters. Photonis also maintains the capability to use 238U as a detection medium for high energy neutrons.

Fission chambers are critical components for reactor neutron flux monitoring and can be used to detect thermal neutrons in high flux, to monitor the reactor fuel burn-up, and to control power in the source, intermediate, and power ranges.

Gas filled neutron detectors are designed to operate in three modes:

- Pulse mode analyzes and counts individual detector pulses, ideal for source range indication

- Fluctuation, or Campbell mode, is used to analyze the fluctuation of the direct current from the detector. This method is excellent at discriminating gamma noise and is ideal for use in the intermediate and power ranges.

- Current mode is used to measure the mean of the direct current from the detector and is typically used for power range detection.

Fission chambers are filled with the appropriate gas for both high-temperature operation and fast response and are extremely radiation resistant.

resistant.

Gamma detection as a technology

In Gamma detectors, gamma radiation produces electrons by interacting with the cathode material and the filling gas. These electrons ionize the gas and the charge carriers are collected by the electrodes. The resulting charge is supplied as a direct current to measurement electronics. The primary electrons are created by several interaction mechanisms:

- Photoelectric effect

- Compton scattering

- Pair production

Mechanism efficiency depends on gamma quanta energy, cathode material and thickness, filling gas type and pressure. Detector sensitivity is therefore very dependent on the detector design, but is always energy-dependent. Due to the dominance of the photoelectric effect, maximum detector sensitivity occurs at about 80 keV. At high gamma energies (> 500 keV), the sensitivity can fall to one hundredth of the maximum for the same mechanical design.

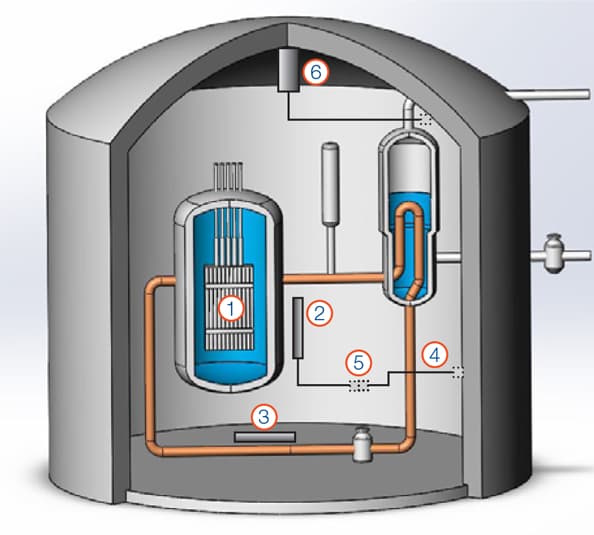

Examples of product applications in a nuclear power plant

1. In-core detectors (Neutron Flux Mapping – I&C)

- Fission chambers 235U

2. Ex-core detector (Neutron Flux Monitoring system – I&C)

- 10B proportional counter for source range

- Fission chambers 235U for intermediate and power ranges.

3. Boron concentration meter (Chemical Monitoring System – I&C)

- 10B proportional counter

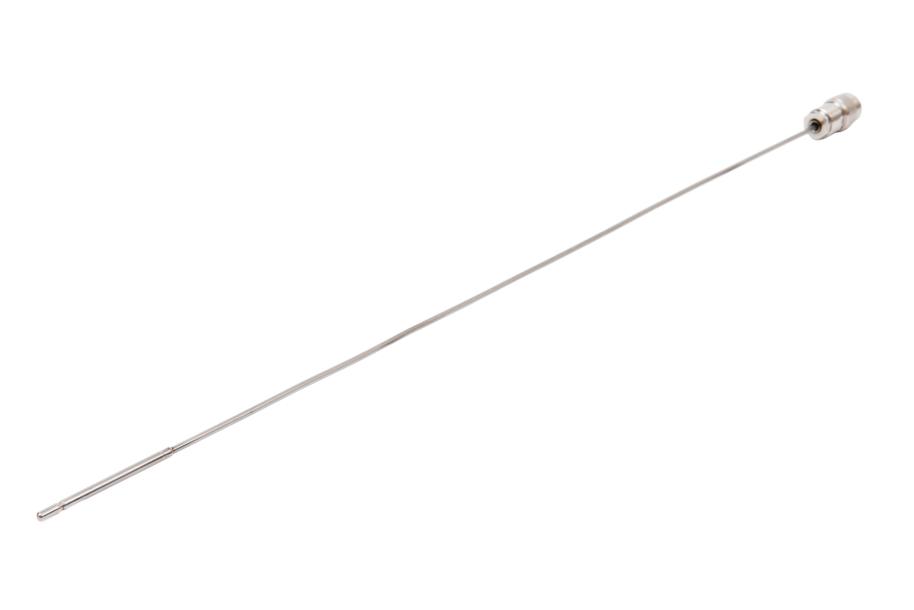

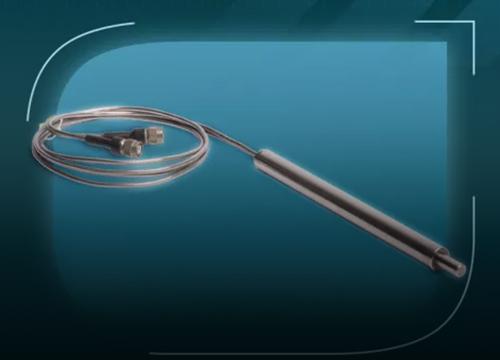

4. MI Cables (Signal transmission system – I&C)

- Mineral insulated cable extension

- Feedthrough

5. Connectors for severe environment

- Signal transmission system – I&C

6. Gamma ion chamber detector (Radiation Monitoring System – I&C)

Decades of Experience and Global Presence

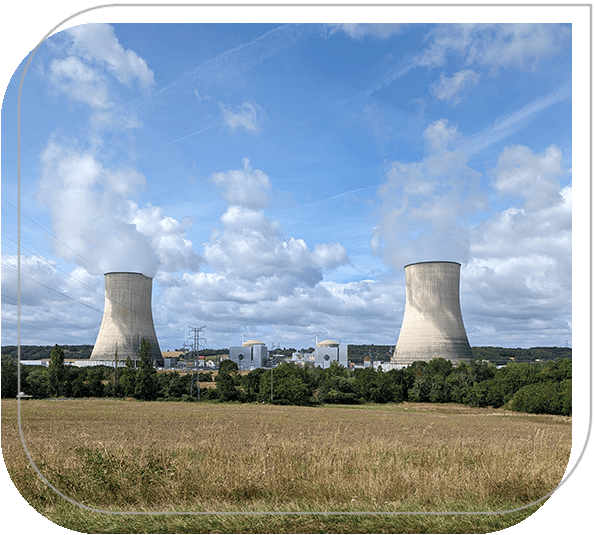

Photonis Nuclear Instrumentation has been a prominent player in the field for over 50 years, gaining extensive knowledge and experience through collaborations with French nuclear power plants and research programs. Over the last decade, their customer base has expanded globally, with partnerships in countries such as Sweden, Bulgaria, China, Czech Republic, Russia, Slovakia, Switzerland, Ukraine, and the USA.

Advanced Nuclear Instrumentation Technology

The Nuclear Instrumentation group at Photonis is dedicated to designing, developing, and implementing specialized instruments that detect, measure, and analyze radiation in various nuclear and radiation-related applications. The group adheres to stringent quality standards, operating according to ISO9001, ISO19443, RCCE (EDF rules), ASME NQA-1, and HAF604.

Tailored Solutions for the Nuclear Industry

Photonis' Neutron and Gamma Detectors are specifically engineered for the nuclear industry, serving critical roles in nuclear power plants, fuel reprocessing facilities, waste storage monitoring, and nuclear research. These detectors play an indispensable role in maintaining safety, particularly in extreme conditions such as high radiation levels, elevated temperatures, high external pressures, and potential Loss of Coolant Accidents (LOCA) and post LOCA scenarios.

Moreover, Photonis supports the specific requirements of Small Modular Reactors (SMR) and Advanced Reactors, aiming to contribute to a sustainable energy future. We partner with reactor developers to provide custom instrumentation solutions for each SMR application.

Versatile Detector Technologies

Photonis excels in offering unique detector technologies that are compatible with various types of reactors and their specific operating environments. Their expertise extends to pressurized water (PWR), boiling water (BWR), heavy water (HWR) reactors, and other reactor designs. Noteworthy collaborations include Électricité de France (EDF), Framatome, the French Alternative Energies and Atomic Energy Commission (CEA), TechnicAtome, and ORANO in France.

Global Reach and Impact

Photonis Nuclear Instrumentation caters to more than 30 countries worldwide, actively contributing its expertise to projects in Argentina, Australia, Canada, China, Russia, South Korea, the United Kingdom, the United States of America, and various Western European nations, among others.

Driving Innovation and Research

Photonis remains at the forefront of innovation and research, actively participating in projects involving fast reactors like Phenix, Superphenix, and the Astrid project. Additionally, they continue to collaborate on research reactors, including the Jules Horowitz Reactor (JHR), and contribute to the Fusion market with projects such as ITER and IFMIF-DONES.

Gamma and Neutron technology from Photonis Nuclear Instrumentation is pivotal in advancing reactor instrumentation and control for safety and research purposes. Our detectors serve as essential components in ensuring the secure and efficient operation of nuclear facilities and research institutions worldwide. Photonis' commitment to quality, innovation, and global collaboration continues to shape the field of nuclear technology, paving the way for a safer and more sustainable future.

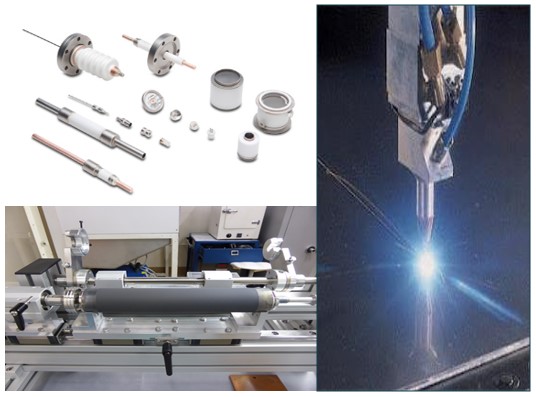

A French Know-How

Proven manufacturing and testing processes through more than 50 years of experience in nuclear instrumentation production.

- Ceramic to metal bonding

- Boron layer deposition by CVD

- HEU layer deposition

- Argon Arc welding

- Laser welding

- Gas filling

- Neutron measurement testing

- Nuclear QA for QRA components

Products 7

See all exosens products

What's new in Gamma and Neutron technology?

See all

Nov 24th 2023

Photonis, part of Exosens, Aids in TerraPower’s Mission

Photonis, part of Exosens, Aids in TerraPower’s Mission of Low-Cost and Carbon-Free Energy Solutions with Key Components of Operation

Apr 09th 2024

Exosens Adds Innovative Photon Counting System, LINCam