In the world of industry and transportation, precision and safety are paramount. That's where Exosens Technology steps in, providing innovative solutions that take control and non-destructive testing to a whole new level.

Infrared (IR) imaging technology provides numerous advantages over visible imaging. One common use of IR imaging is its ability to image even in low light conditions. IR imaging also enhances vision capabilities during unfavourable weather conditions.

Need some answers? Ask our experts!

Contact us

Test and evaluate without any damage

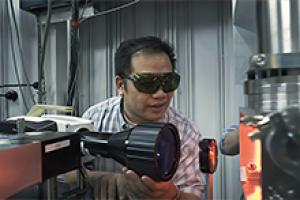

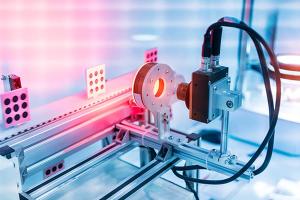

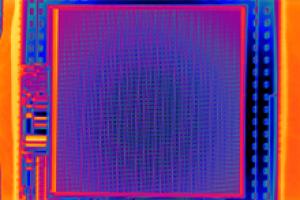

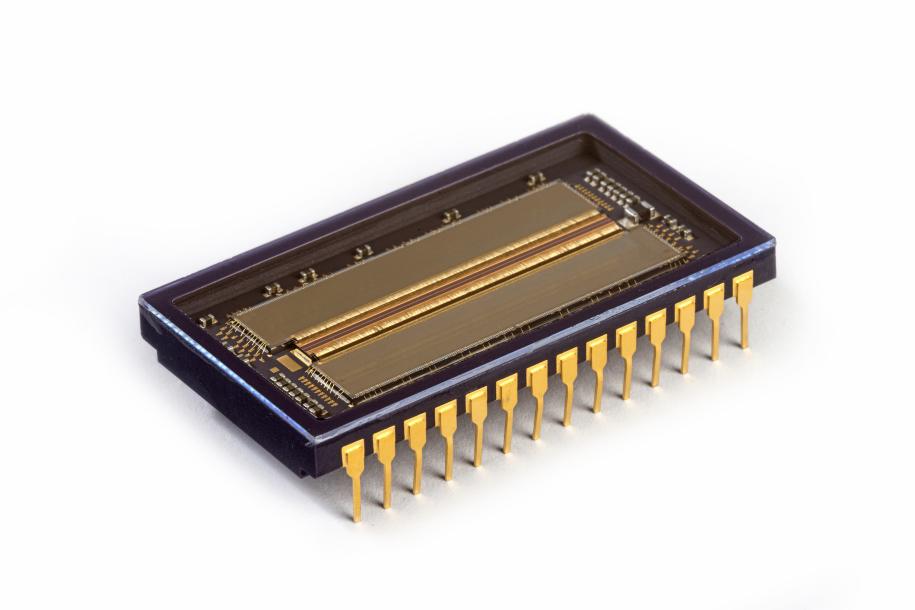

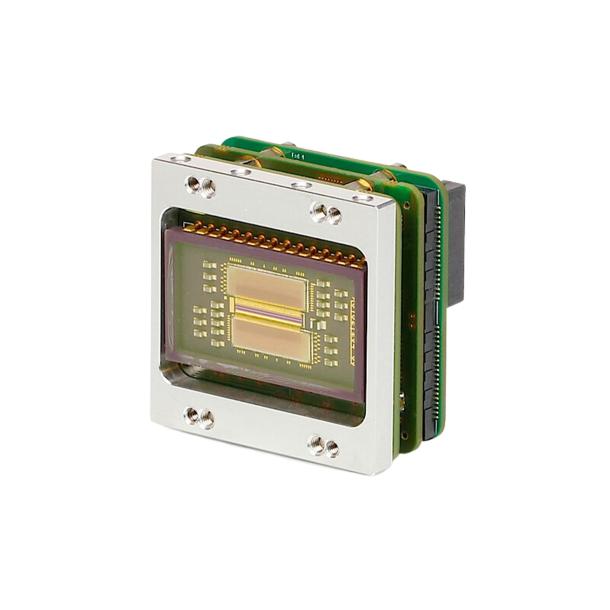

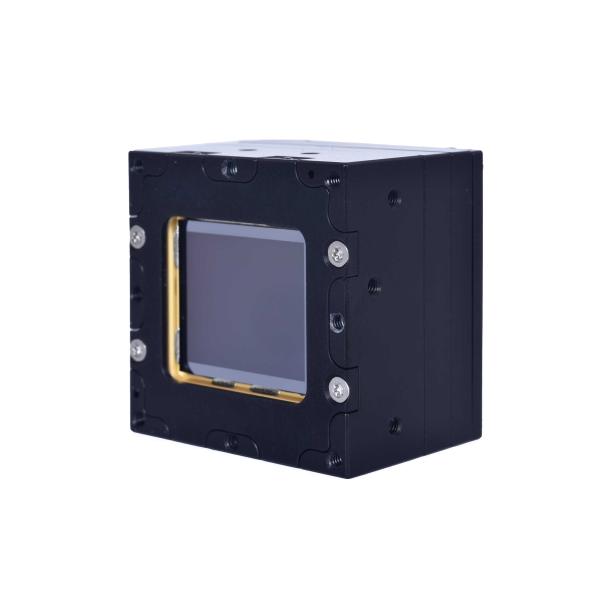

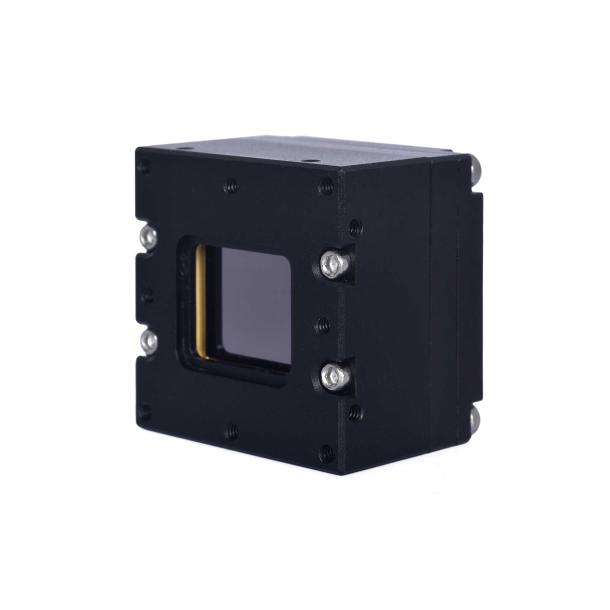

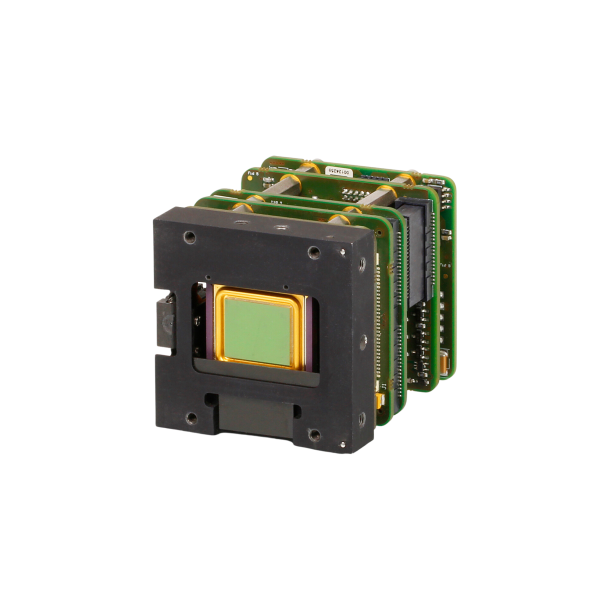

Non-destructive testing, also referred as NDT, covers all the techniques used to analyse something without damaging it. Most of NDT methods are using visual inspection or XRay analysis. NDT has been used in a wide variety of different markets such as food, automotive, aerospace and semiconductors. Functionalities are numerous: control the product quality in the manufacturing line (Machine Vision), check the manufacturing process for defaults, contribute to prevent damage in High Voltage lines (PowerGrid maintenance), analyse the chemical composition of materials and the analysis of the shape of a laser beam or a combustion flow.

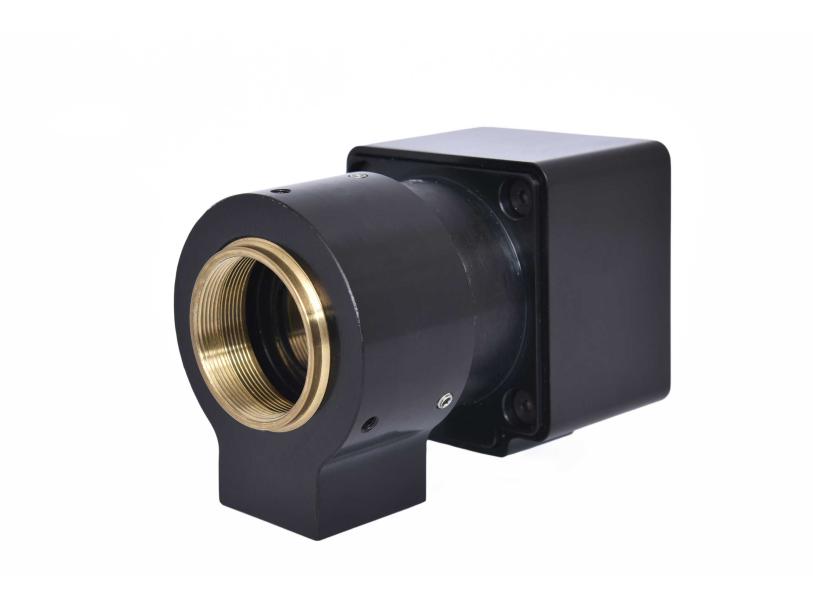

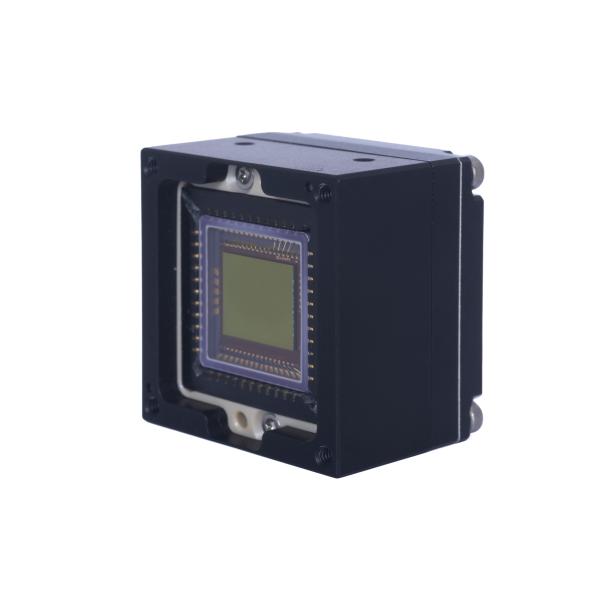

Exosens offers to OEMs and integrators intensified cameras (from Ultra-Violet (UV) to Near Infra-Red (NIR)) and infrared cameras (Short Wave Infra-Red (SWIR) or Long Wave Infra-Red (LWIR)) to support these challenges. Each bandwidth contributes to see specific defaults and could be used in combination to optimise the control efficiency. Exosens cameras are compact, easy to use, with standard interfaces to be easily integrated.

Improving Transportation Safety and Efficiency through Better Vision

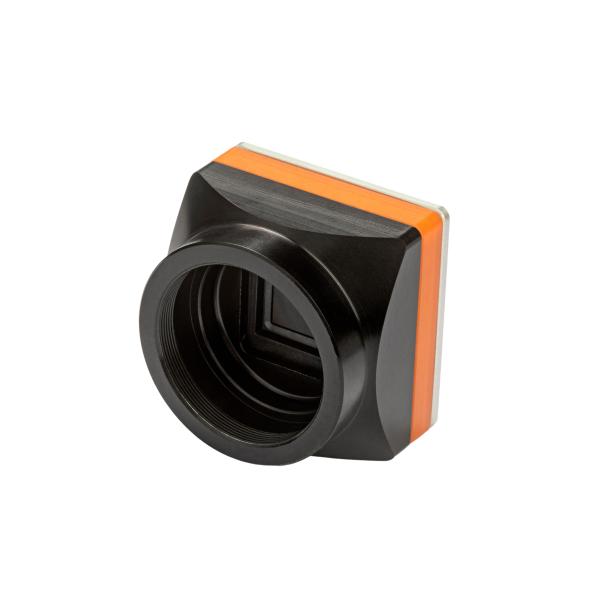

Vision is an essential aspect of any successful transportation operation. Clear visibility allows drivers, pilots, and operators to see their surroundings and avoid potential hazards, ultimately ensuring safe and efficient operations. However, in certain situations, visibility can be limited by low-light conditions or inclement weather such as snow, rain, and fog. This is where infrared (IR) imaging Exosens technology comes in to enhance vision capabilities and provide a more accurate depiction of the environment.

At Exosens, we specialize in developing and deploying IR imaging systems that enhance visibility for various transportation operations. Our Exosens cameras are integrated into vision enhancement systems that are designed to provide a superior perception of the environment and to improve operator visibility. These systems can be deployed in various modes of transportation, including train, airborne, road, and maritime operations. By increasing visibility, our systems can help operators avoid potential hazards and ensure safer and more efficient operations. Overall, our Exosens technology provides operators with a distinct advantage in low-light or adverse weather conditions, ultimately leading to safer transportation operations.

Products 38

See all exosens products

![Neutronic [i] neutronic.](https://www.exosens.com/sites/default/files/styles/product/public/2022-09/neutronic.png?itok=r881fmO8)