Microchannel plates

Microchannel plates (MCPs) from Photonis are made from a proprietary glass formula, which ensures the highest quality and longest life of any other commercially available MCP.

Microchannel plates

Contact sales or request a quote

Contact usDescription

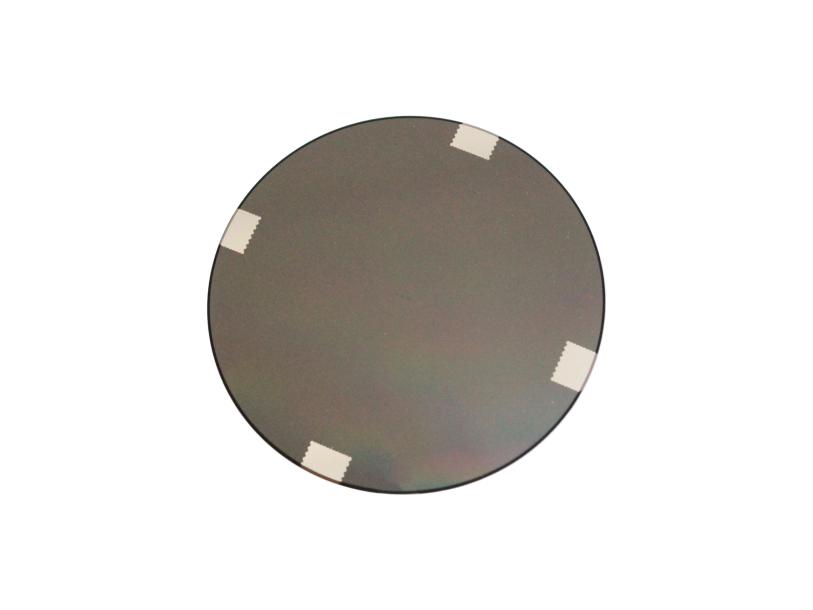

As the leading provider of MCPs for electron multiplication, Photonis provides our MCPs in a variety of custom sizes (4mm to 150mm) and configurations (Z-Stack or Chevron). Our extended dynamic range output option increases detection up to ten times over traditional MCPs. Available in detection, image, and premium grades, Photonis’ MCPs are designed to provide stable gain and outstanding bias current stability. You can specify the pitch/pore size as well as the shape, size, and configuration. By partnering with Photonis for all of your MCP needs, you will get a detector exactly suited to your needs.

MountingPad™ Technology

MountingPad™ MCPs are rimless microchannel plates which have been patented to prevent excessive noise due to trapped gas or damaged pores near the edges from mounting the MCP. Our MountingPad™ technology provides a rigid area to attach the MCP without damaging pores, yet provides a gap between the active channels and the mounting hardware. This gap allows gas to vent, eliminating plasma discharges which cause excessive noise.

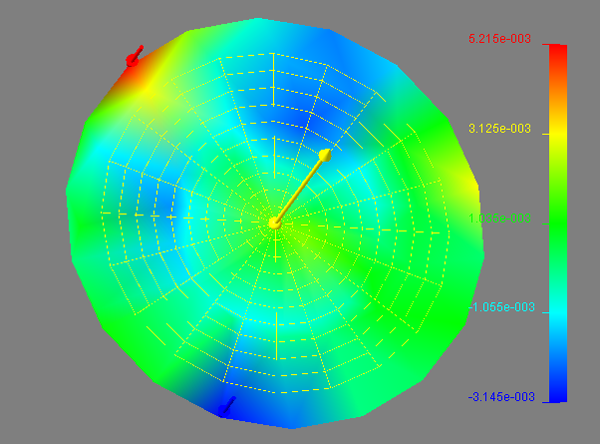

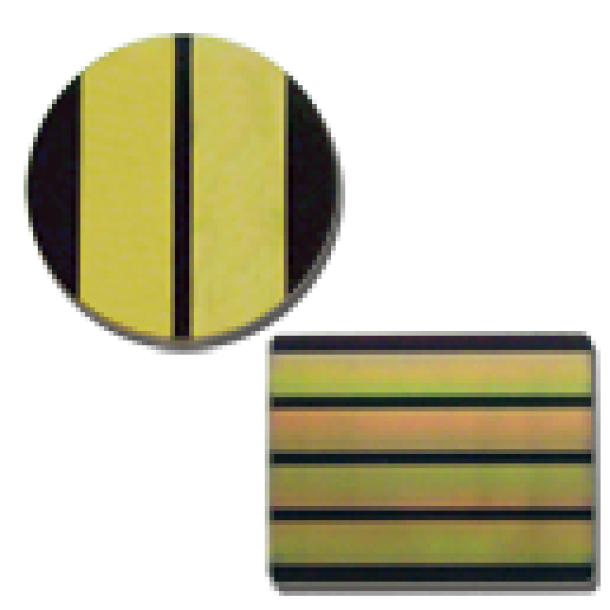

Improving TOF-MS Instruments Using TruFlite™ MCP

Photonis’ TruFlite™ microchannel plates provide a clear advantage to competitors’ products. Their superior flatness reduces time jitter and ion arrival time, as demonstrated below. If you are looking to improve the results of your TOF-MS instrument, upgrade your detector to include a TruFlite™ MCP.